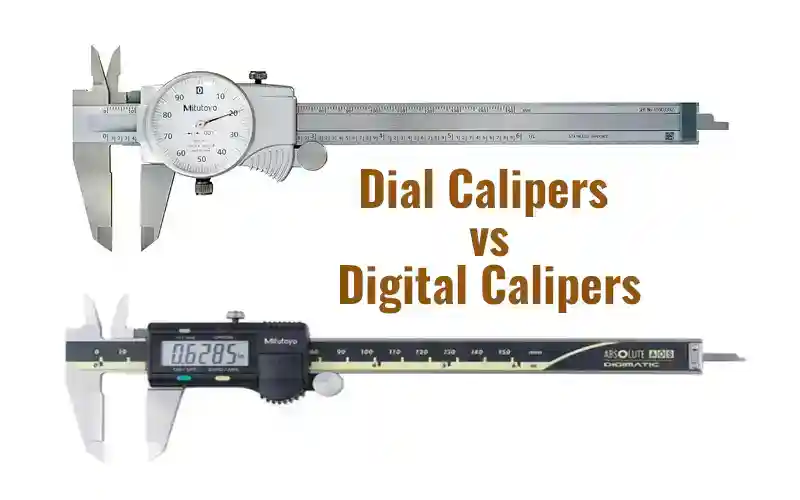

Certainly! Let’s explore the differences between dial calipers and digital calipers—two essential measuring tools used in various fields. In this article, we’ll explore the distinctions between dial calipers vs digital calipers, helping you understand which one may be better suited for your specific needs.

Dial calipers and digital calipers are tools used in factories, engineering, research, and other places. People pick between dial calipers and digital calipers based on what they need and how much money they have. Let’s learn more about the differences between them.

History of Calipers

Calipers have a long history, dating back to ancient civilizations like the Greeks and Romans. They were used for measuring length and dimensions. Over time, calipers evolved into more sophisticated instruments, leading to the development of dial calipers and digital calipers in modern times.

Ancient Beginnings:

The earliest known caliper dates back to the 6th century BC, found near the Italian island of Giglio. It was made of wood and had a fixed and movable jaw for measuring dimensions. Both the Greeks and Romans used calipers for precise measurements.

Chinese Contribution:

In 9 AD, during the Chinese Xin Dynasty, a bronze caliper with a “slot and pin” design was used for minute measurements. It was graduated in inches and tenths of an inch.

Pierre Vernier’s Innovation:

The modern vernier caliper was developed by Pierre Vernier, improving upon Pedro Nunes’s nonius scale. Vernier’s design enhanced accuracy and became widely used in various fields.

Types of Calipers:

- Inside Calipers: Measure internal size with manual or screw adjustments.

- Outside Calipers: Measure external dimensions.

- Vernier Calipers: Feature a sliding scale for precise readings.

- Digital Calipers: Display measurements digitally.

- Depth Calipers: Measure depth or height.

- Dial Calipers: Equipped with a dial gauge for easy reading.

- Micrometer Calipers: A form of caliper, distinguished for precise machine-shop usage.

Terminology:

- American spelling: “caliper”; British spelling: “calliper”.

- “Calipers” is both singular and plural.

- “Pair of verniers” may refer to a vernier caliper, even if it doesn’t always include a vernier scale.

Dial Calipers VS Digital calipers

Dial Calipers

Overview

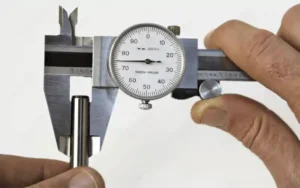

- Dial calipers are mechanical inspection tools designed for precise measurements.

- They can measure internal, external, step, and depth dimensions with an accuracy of approximately +/- 0.001 inches or +/- 0.02 mm.

- Commonly available in measuring ranges such as 0-6 inches, they also come in variations like 0-4 inches, 0-8 inches, 0-12 inches, and even 0-24 inches.

- The distinctive feature of dial calipers is the rack-and-pinion system that drives the indicator needle on the dial face.

Advantages

- No Batteries Required: Dial calipers operate without batteries, making them reliable and always ready for use.

- Tried and True Design: Their mechanical construction has stood the test of time.

Disadvantages

- Unit Limitation: Dial calipers cannot easily switch between inches and millimeters.

Digital Calipers

Overview

- Digital calipers share similarities with dial calipers in terms of accuracy and measuring ranges.

- The key difference lies in their LCD display, which requires batteries for operation.

- Digital calipers are available in both metric and imperial units.

Advantages

- Instant Measurements: The LCD display provides immediate readings, eliminating the need to interpret dial faces and scales.

- Dual Unit Capability: Digital calipers can seamlessly switch between inches and millimeters at the push of a button.

Disadvantages

- Battery Dependency: Digital calipers rely on batteries, which can run out or fail.

- Electronics Susceptibility: The electronic components may be vulnerable to damage.

Working Principle

Dial calipers operate based on a mechanical principle, utilizing a dial indicator to provide measurement readouts on a circular scale. In contrast, digital calipers use electronic sensors and digital displays to offer precise numerical measurements.

Accuracy and Precision

Both dial calipers and digital calipers offer high levels of accuracy and precision when used correctly. Dial calipers typically have a resolution of 0.001 inch or 0.02 millimeters, while digital calipers offer even greater accuracy with resolutions as fine as 0.0005 inch or 0.01 millimeters.

Ease of Use

Dial calipers feature a simple analog dial indicator, making them intuitive to read for users familiar with analog gauges. Digital calipers, with their digital displays, provide numerical measurements, eliminating the need for interpretation and reducing the likelihood of reading errors.

Measurement Range

Dial calipers and digital calipers typically offer similar measurement ranges, with some models capable of measuring up to 12 inches or 300 millimeters. Users should select a caliper size that accommodates the range of dimensions encountered in their specific application.

Resolution

Resolution refers to the smallest incremental measurement that a caliper can display. Digital calipers offer higher resolution capabilities compared to dial calipers, allowing for more precise measurements.

Durability and Longevity

Both dial calipers and digital calipers are durable and reliable tools when properly maintained. Dial calipers are known for their mechanical simplicity, while digital calipers may require extra care due to their electronic components.

Battery Dependency

Digital calipers rely on batteries to power their electronic components, introducing the risk of downtime if the batteries run out. Dial calipers, being mechanical, do not require batteries for operation.

Cost Considerations

Dial calipers are generally more affordable than digital calipers, making them suitable for budget-conscious users or applications where high precision is not required. Digital calipers offer additional features and capabilities, justifying their higher cost for certain users.

Environmental Considerations

Dial calipers, with their mechanical construction, are generally more resistant to environmental factors such as dust and moisture. Digital calipers may be more susceptible to damage from moisture or contaminants due to their electronic components.

Calibration Requirements

Both dial calipers and digital calipers require periodic calibration to maintain accuracy. Dial calipers typically require manual calibration, while digital calipers may offer automatic calibration features.

Applications in Industries

Dial calipers and digital calipers find applications across various industries, including manufacturing, engineering, research, and quality control. Their versatility and accuracy make them indispensable tools in precision measurement tasks.

User Preferences and Recommendations

The choice between dial calipers and digital calipers depends on factors such as accuracy requirements, ease of use preferences, budget constraints, and specific application needs. Users should consider these factors when selecting the appropriate caliper for their requirements.

Future Trends and Innovations

Advancements in technology are likely to drive further innovation in caliper design and functionality. Emerging trends such as wireless connectivity and augmented reality interfaces may revolutionize how calipers are used in industrial workflows.

Conclusion

In conclusion, this article has discussed dial calipers vs digital calipers in detail. They are both essential tools in precision measurement applications, each offering unique features and capabilities.

By understanding the differences between the two types of calipers and considering factors such as accuracy, ease of use, durability, and cost, users can make informed decisions when selecting the most suitable tool for their measurement needs.

FAQs for Dial Calipers vs Digital Calipers

Q. Are dial calipers more accurate than digital calipers?

Answer: Both dial calipers and digital calipers offer high levels of accuracy, but digital calipers may provide slightly better precision due to their digital readouts.

Q. Do digital calipers require batteries to operate?

Answer: Yes, digital calipers rely on batteries to power their electronic components, while dial calipers do not require batteries.

Q. Can dial calipers be used in wet or dusty environments?

Answer: Dial calipers are generally more resistant to environmental factors such as dust and moisture compared to digital calipers.

Q. How often should calipers be calibrated?

Answer: Both dial calipers and digital calipers require periodic calibration to maintain accuracy, typically recommended at least once a year.

Q. What factors should I consider when choosing between dial and digital calipers?

Answer: Factors to consider include accuracy requirements, ease of use preferences, budget constraints, and specific application needs.