Hello everyone, today we’re going to take a look at both measurement dial calipers proper technique for using them as well as some care and maintenance tips. Here we describe “How to read dial calipers” in easy and effective way.

Dial calipers are essential tools in various industries. Which provides precise measurements for a wide range of applications.

Mastering the basics of dial caliper reading is required for accurate measurement and quality assurance in manufacturing, engineering and other fields.

Understanding Dial Calipers

Dial calipers are precision measuring instruments. Which is used to measure linear dimensions such as length, width, and thickness.

They consist of a main scale, a sliding jaw, a vernier scale, and a dial indicator. There are different types of dial calipers. For example: standard, digital and special-purpose models.

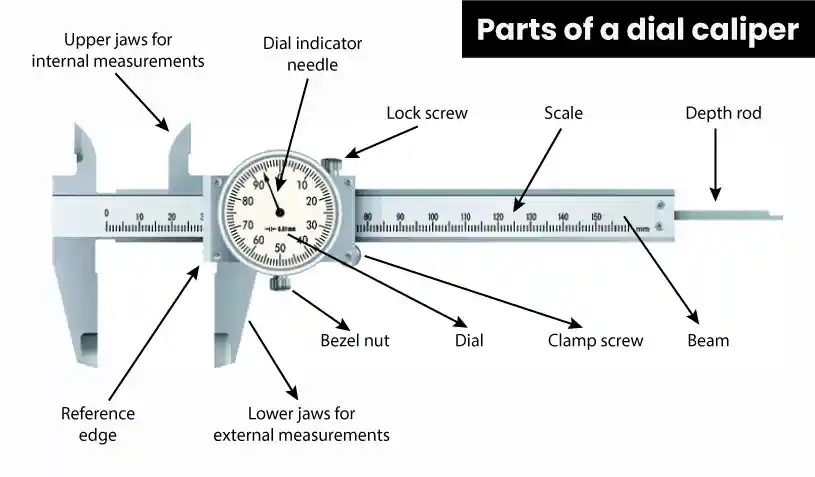

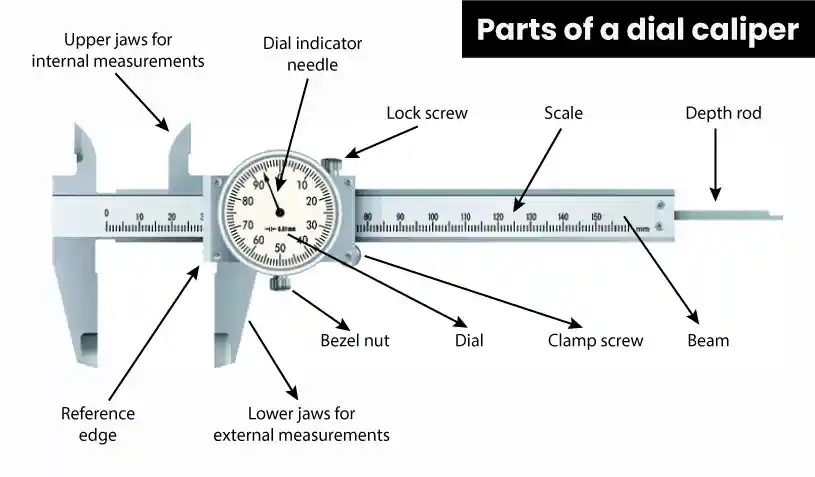

Different Parts of Dial Calipers

Different main parts of a dial calipers: Upper jaws for internal measurements, Dial indicator needle, Lock screw, Scale, Depth rod, Clamp screw, Dial, Bezel nut, Beam, Reference edge, Lower jaws for external measurements.

Tools Required

To read dial calipers effectively, you will need the following tools:

- Dial calipers: Choose a high-quality caliper with clear markings and smooth operation.

- Workpiece for measurement: This can be any object or material you need to measure.

- Proper lighting: Adequate lighting is essential for accurate readings, especially when measuring small or intricate parts.

Calibration and Zeroing

Calibrating your dial calipers is crucial for accuracy. Before use, ensure that the calipers are zeroed properly by aligning the jaws and adjusting the dial indicator to read zero. Regular calibration checks will help maintain accuracy over time.

Reading the Main Scale

The main scale on dial calipers is typically divided into inches and millimeters. To read the main scale, locate the zero mark and identify the position of the jaws relative to the scale divisions. Read the measurement directly from the main scale.

Interpreting the Vernier Scale

The vernier scale helps you measure things more precisely than the main scale. You can see smaller measurements between the main scale lines.

First, line up the zero mark on the vernier scale with a line on the main scale. Then, look at which vernier scale line lines up with a line on the main scale.

The number of the smallest line on the vernier scale shows how much more you’ve measured than what’s on the main scale.

Reading Dial Indicator

The dial shows measurements in tiny bits, like parts of an inch or parts of a millimeter. Look at where the needle is on the dial to understand the measurement. Make sure the dial is set right to get the right numbers.

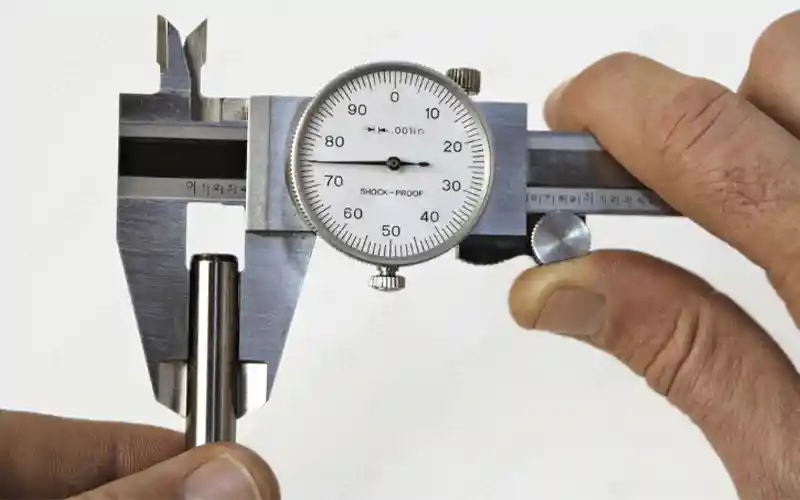

Basic Measurement Techniques

Dial calipers can be used for various types of measurements, including:

- External measurements: Place the object between the jaws and close them gently to obtain the measurement.

- Internal measurements: Insert the jaws into a hole or opening and open them until they make contact with the sides.

- Depth measurements: Extend the depth rod to the bottom of the recess and take the reading from the dial indicator.

Practice Exercises

To improve your skills in reading dial calipers, try the following exercises:

- Measure the dimensions of different objects using external and internal measurements.

- Practice zeroing the calipers and calibrating the dial indicator for accurate readings.

- Measure the depth of holes or recesses to enhance your proficiency in depth measurements.

Common Mistakes to Avoid

Avoid the following mistakes when using dial calipers:

- Misinterpreting readings due to parallax or improper alignment.

- Forgetting to zero the calipers before taking measurements.

- Using excessive force, which can damage the jaws and affect accuracy.

Advanced Techniques

For more complex measurements, consider the following techniques:

- Reading non-linear scales: Some dial calipers feature non-linear scales for specialized applications. Familiarize yourself with the scale’s markings and interpretation methods.

- Measuring irregular shapes: Use the jaws and depth rod creatively to measure irregularly shaped objects accurately.

- Calculating tolerances: Understand how to calculate tolerances based on the precision of your dial calipers and the requirements of the project.

Maintenance and Care

Proper maintenance is essential for prolonging the life of your dial calipers. Follow these tips:

- Clean the calipers regularly with a soft cloth and lubricate the moving parts to ensure smooth operation.

- Store the calipers in a protective case or pouch to prevent damage and contamination.

- Inspect the calipers regularly for signs of wear and tear, such as worn jaws or loose components.

Applications in Various Industries

Dial calipers find applications in a wide range of industries, including:

- Manufacturing: Precision machining, quality control, and inspection processes.

- Engineering: Design and prototyping, dimensional analysis, and assembly verification.

- Automotive: Engine building, chassis fabrication, and performance tuning.

- Aerospace: Aircraft maintenance, component fabrication, and composite material analysis.

Troubleshooting

If you encounter measurement errors or inconsistencies, consider the following troubleshooting steps:

- Check the alignment of the jaws and the zero position of the dial indicator.

- Verify that the calipers are clean and free from debris that could interfere with the measurements.

- Inspect the condition of the calipers for any signs of damage or wear that may affect accuracy.

Comparing Dial Calipers with Other Measurement Tools

While dial calipers are versatile and accurate tools, they have some limitations compared to other measurement instruments, such as:

- Vernier calipers: Offer similar functionality but require more manual dexterity to read accurately.

- Digital calipers: Provide instant digital readouts for quick and precise measurements but may be less durable in harsh environments.

- Micrometers: Ideal for measuring small dimensions with high precision but may be more cumbersome to use for larger objects.

Safety Precautions

When using dial calipers, observe the following safety precautions:

- Handle sharp edges and objects with care to avoid injury.

- Avoid over-tightening the jaws, which can damage delicate components.

- Wear appropriate personal protective equipment, such as safety glasses or gloves, when working with hazardous materials or environments.

Online Resources and Further Learning

Explore the following resources for additional information and learning opportunities:

- Websites: Visit reputable websites dedicated to metrology, machining, and engineering for tutorials, articles, and forums.

- Video demonstrations: Watch instructional videos on platforms like YouTube to see dial calipers in action and learn tips from experienced users.

- Advanced courses: Consider enrolling in formal training programs or workshops to enhance your skills in metrology and precision measurement.

Conclusion

Learning how to read dial calipers is important for measuring things exactly. To do it well, you need to know what parts the calipers have, how to measure correctly, and practice a lot. Here we include the topics “how to read dial calipers”. Also, make sure to stay safe, take care of your tools, and keep learning more.

References

- Smith, John. “Precision Measurement Techniques.” McGraw-Hill Education, 2019.

- Jones, Emily. “Metrology for Engineers.” Cambridge University Press, 2020.

Glossary

- Metrology: The science of measurement, including measurement techniques, standards, and instrumentation.

- Parallax: The apparent shift in position of an object when viewed from different angles, leading to inaccuracies in measurement.

- Tolerance: The allowable deviation from a specified dimension or value in manufacturing or engineering.