Good day. If you are looking for knowledge about sledge hammers, then you’ve come to the right place.

Sledge hammers are symbols of strength and demolition; they have been a staple in toolboxes for centuries.

Here, we will cover the history, types, uses, safety tips, and maintenance care.

Table of Contents

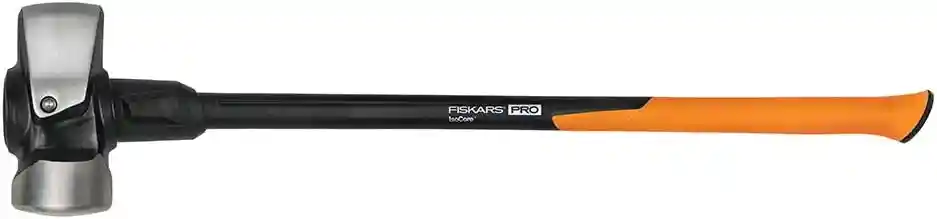

What is a Sledge Hammer?

A sledge hammer is a heavy-duty tool. A large, flat, metal head is attached to a long handle. It delivers high-impact force, and people commonly use it for demolition, driving stakes, and other heavy-duty applications.

History of Sledge Hammers

Early civilizations used them for building and crafting. In ancient Egypt, large wooden mallets helped construct monumental structures like the pyramids.

Over time, these tools evolved, adopting iron and steel for excellent durability and efficiency. Today, modern sledgehammers feature ergonomic designs and advanced materials, making them essential in both professional and DIY settings.

Types of Sledge Hammers?

Standard

Standard sledgehammers have a long handle and a heavy, double-faced head. They are ideal for breaking concrete, driving stakes, and demolition work.

Specialty

Designers create specialty sledgehammers. These include dead blow hammers and engineer’s hammers tailored for specific tasks. Dead blow hammers reduce rebound and prevent damage to delicate surfaces, while engineer’s hammers offer precision in metalworking.

Sizes and Weights

Sledgehammers vary in size and weight, typically ranging from 2 to 20 pounds. Lighter sledgehammers are easier to control, making them suitable for precision work. Heavier sledgehammers deliver more force, making them ideal for heavy demolition.

Uses of Sledge Hammers

Construction

In construction, sledgehammers are invaluable for tasks such as breaking concrete, driving rebar into the ground, and demolishing walls. Their robust design allows workers to exert significant force with each swing.

Home Improvement

Sledgehammers are helpful for DIY projects at home. People use them to break walls and take out old floors. They are also suitable for hammering large nails or stakes into the ground.

Industrial Applications

Industries such as metalworking and forging rely on sledgehammers to shape metal and perform heavy-duty tasks. Their ability to deliver controlled, powerful strikes makes them essential tools in these environments.

Emergency

In emergencies, firefighters and rescue teams use sledge hammers to break through barriers and access trapped individuals. Their reliability and strength make them critical in life-saving scenarios.

Choosing the Right Sledge Hammer

Task-Specific Considerations

When selecting the best sledge hammer, consider the specific tasks you’ll be performing. For demolition, a heavier hammer provides more impact. For precision tasks, a lighter hammer with a shorter handle offers better control.

Material and Build Quality

Choose a sledge hammer with a durable handle made of fiberglass or high-quality wood. Fiberglass handles are strong and can withstand different weather conditions. Wooden handles have a traditional appearance and are simple to replace if they break.

Grip and Comfort

A comfortable, non-slip grip is essential for safe and effective use. Look for sledge hammers with cushioned handles that reduce vibration and prevent hand fatigue.

Weight and Balance

Select a hammer weight that you can comfortably handle. A well-balanced sledge hammer ensures better control and reduces the risk of injury.

Safety Tips

Proper Technique

To use a sledge hammer safely, stand with your feet shoulder-width apart, grip the handle firmly, and swing with controlled force. Keep your back straight, and use your legs and arms to generate power.

Protective Gear

Ensure to wear safety goggles, gloves, and sturdy footwear when using a sledgehammer. Protective gear minimizes the risk of injury from flying debris and accidental slips.

Maintenance and Inspection

Regularly inspect your sledge hammer for signs of wear, such as handle cracks or a loose head. Address any issues immediately to ensure the tool remains safe to use.

Maintenance and Care

Cleaning and Storage

After use, clean your sledge hammer to remove dirt and debris. Storing the item in a dry place is essential to prevent rust from forming. Long-term exposure to oxygen and moisture causes metals to rust.

By keeping the item in a dry environment, you can help protect it from rust and prolong its lifespan. Additionally, storing the item in a dry place also helps prevent other forms of damage, such as mold or mildew growth. Be sure to regularly check the storage area to ensure it remains dry and free from moisture.

Handle Replacement

You should promptly replace the handle if it sustains damage. Many sledge hammers allow for easy handle replacement, ensuring the tool’s longevity.

Head Care

Keep the hammer head in good condition by checking for chips or cracks. If the head sustains damage, you must repair or replace it.

Conclusion

A sledgehammer is a powerful tool that, when used correctly, must have a significant impact on your work. Always prioritize safety and maintenance for a long-lasting tool.

FAQs

Q. What are the most common sizes of sledgehammers?

Answer: Sledge hammers typically range from 2 to 20 pounds, with the 8-pound hammer being a popular choice for flexibility.

Q2. How do I maintain my sledge hammer?

Answer: Please keep it clean, inspect it regularly for damage, and store it in a dry place to prevent rust.

Q3. What safety equipment should I use with a sledge hammer?

Answer: Wearing safety equipment such as gloves, safety goggles, and sturdy footwear is essential.

Q4. Can someone use a sledgehammer to break concrete?

Answer: Yes, a heavy-duty sledge hammer is effective for breaking up concrete.

Q5. What should I look for when buying a sledge hammer?

Answer: Consider the weight, handle material, and head design to find a hammer that suits your needs.

Related article: Ball Peen Hammer: A Comprehensive Guide